"Test-Rad" Regolith Mitigation Technology Design for NASA

Designing a three-layer Lunar Dust Mitigation technology for NASA's Big Idea Challenge

Overview

Our team RISD & Brown team is 1 of the 7 teams selected by NASA out of 80+ university teams to be awarded a portion of the $1 million dollars in funding!

The Mission

The Big Idea Challenge is a graduate school & PhD level contest hosted by NASA. In this challenge, teams design, build, and test new dust mitigation technologies that can be applied in lunar applications. Our objective is to design a solution for pertinent issues such as dust clinging to spacesuits and optical systems, dust clouds that form upon landing, and hazardous in-cabin particulate levels.

Who it's for:

NASA The National Institute of Aerospace (NIA)

Time Frame

October 2020 - December 2021

Team: 16 people

My Role:

Designer,

Prototyping, Apparatus Designs

Video and Graphics Lead

Technical Writer

All Teams:

Matlab Modeling

Applications Research

Fibers Prototyping

Static Generator

Writing

Video and Graphics

Publications:

Design Objectives

Design Goal

To prevent damage to life support functionalities, reduce the deterioration of the seals on the suit, and create a higher standard of safety for astronauts.

Challenges:

The finer regolith, or lunar dust, derived from the coarser soil is one of the “principal limiting factors” for extended moonwalks, which will be occurring frequently during the Artemis missions.

- Regolith is highly abrasive, cohesive, and adhesive. The latter is due to the dust’s tendency to be electrostatically charged and aggravates the dust removal process.

- lunar dust affects all outer garments, especially lower limbs, seals, and bearings. Extensive wear of these sensitive joints over long periods of time could potentially induce catastrophic failures of the suit.

The Design

TEST-RAD: Tufted Electrostatic Solution To Regolith Adhesion Dilemma

- Provides systematic layers of protection from electrostatically charged regolith at the spacesuit’s most vulnerable points. This will be accomplished by prototyping a dense, three-layer system attached to suits at the joints where abrasion is most likely to occur.

.png)

These areas include the knees, lower legs, the abdominal seal, and possibly the shoulder seal, as well as bearings.

TEST-RAD consists of 3 layers.

1. A backing fabric that directly attaches to the suit and acts as an insulator to stop charge proliferation from the middle layer.

2. A middle layer consisting of an electrostatic system that takes advantage of the charged nature of regolith and repels it from the suit.

The system of repulsion is created by wires connecting to a stainless steel mesh which then transfers charge to the tufted fibers, which make up the conductive outermost layer. The life support system of the spacesuit provides power to this system through the use of a static generator.

3. There are additional clusters of shorter, non-conductive, catching fibers lying underneath the conductive layer which accumulate any dust particles able to penetrate the electrostatic barrier.

There are three physical characteristics of the lunar regolith by which TEST-RAD will utilize in protecting the suit-wearer: shape, size and charge. Test Rad combines two technologies intended to stop the penetration of regolith into fabric or seals. It uses electrostatic shielding combined with a novel tufted fiber to repel same-charge particles.

Electrostatic shielding is an already proven concept for the repulsion of lunar dust.

However, due to the variation in regolith size and shape, coupled with the additional stress put on suits during EVA, this mitigation technique alone is not significant enough to fully protect the suit. Our addition of densely packed fibers design is inspired by the impenetrable density of chinchilla fur. It blocks out sharp dust particles aims to provide a complete solution to that problem. The tufted fibers will provide a physical barrier between the electrostatic generation assembly (EGA) and the regolith.

Concept & Proposal Video

Prototyping

The evolution of TEST-RAD. All Marks of TEST-RAD lined up along with the bipolar generator iterations. Many iterations were made in order to test out the best conductive fiber to be used for TEST-RAD.

TEST-RAD was handmade and the fibers braided and trimmed by hand. Different braiding and arrangement methods were being tested before we arrived at Mark 3.2

The final Mark of our system was applied to a junction box. This is to show that other than application on the spacesuit, TEST-RAD could be applied on VIPER battery cover boxes, rover gearboxes, and many other types of equipment that are exposed to lunar surface dust.

Testing & Verification on Earth

Testing of TEST-RAD primarily assessed its ability to repel charged lunar regolith simulant which serves as a proxy for how much protection the prototype would provide on the Moon. To reach a Technology Readiness Level (TRL) of 4, a regolith simulant with similar size, electrostatic nature, and abrasive characteristics as lunar dust was used in a laboratory simulated environment.

Lunar Dust Simulant Creation

The abrasive nature and size of lunar dust can be matched by regolith simulants.

We created filtered simulant out of high fidelity simulants purchased from Off Planet Research,

The filtering process consisted of adding water to the simulant, passing the mixture through a fabric filter, and boiling off the water at the end.

To simulate the charged characteristics of lunar regolith, we used an IONFIX Static Generator from TAKK Industries to generate a static charge on our lunar simulant.

Laboratory Testing

.jpg)

In addition to testing at NASA The National Institute of Aerospace (NIA), Test-Rad was subject to various phases of regolith simulant tests in simulated environments like the vacuum chamber and glove box.

The Pass-over Test

The pass-over test involved passing TEST-RAD approximately 3 cm over a simulant-covered charged plate, with both the same electric charge sign.

The Push-over Test

The push test consisted of pushing positively and negatively charged simulant directly from the simulant charging apparatus onto TEST-RAD, with the distance of the furthest particles recorded. This test simulated the regolith coming into direct contact with TEST-RAD and showed how the system is capable of repelling dust a significant distance away from a given apparatus.

The Junction Box Test

The junction box test was designed to check if TEST-RAD can prevent dust from accumulating in sensitive areas of a given apparatus.

Despite successful active repulsion in the pass-over and push testing scenarios, it is not possible in the junction box testing as they were unable to use electrostatically charged simulant. However, the passive system made up for this shortcoming and verified that, in the event of an EGA failure, TEST-RAD still maintains the majority of its dust mitigation capabilities.

Significance

Direct Impact:

Improve the safety of astronauts on extended moonwalks through the deflection of regolith. Specifically, it optimizes the durability and functionality of key sections of the suit, such as joints, bearings, and seals. It will also lessen the amount of free regolith in habitation modules as dust particles are actively repelled from the fabric. Lastly, it should decrease the time needed for overall suit cleaning which should help the crew focus on much more significant tasks.

Impact on NASA's Artemis Missions:

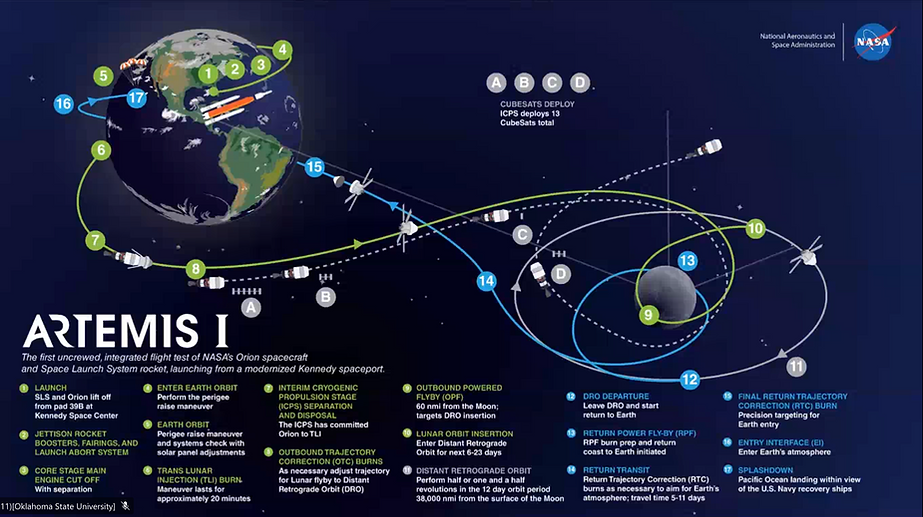

One of the center points of the NASA Artemis missions is the establishment of a long-duration crew presence on the moon to conduct science and to itself be a testing ground for future missions further into space. One of the major aspects of the on-surface parts of the mission is the ability to traverse the surface of the moon on a totally new scale. TEST-RAD fits perfectly into this goal of the Artemis missions as this system will create more opportunities for easier and safer travel, extending the life of suits and their components by limiting detrimental interactions with regolith.

The “Scientific Themes for Human Lunar Return” are the following:

(1) Bombardment of the Earth-Moon System,

(2) Lunar processes and history,

(3) Scientific resources in the permanently shadowed polar environment,

(4) Regolith as the recorder of the Sun’s history,

(5) Biomedicine,

(6) Using the Moon’s resources,

(7) Astronomy

It is clear that 5 out of the 7 goals present a direct need for lunar contact and exploration outside of pressurized environments (such as the habitation area or the habitable mobility platform). With this much expected EVA time it follows that technology for efficient and safe EVA will be of high priority, TEST-RAD will be one part of the EVA system adding a meaningful contribution of safety and efficiency to the system overall.

Conclusions

-

TEST-RAD achieved successful individual verification of both the fiber system and electrostatic generation assembly and partial verification of the hybrid mitigation approach.

-

TEST-RAD’s novel hybrid mitigation strategy warrants further research, specifically to delve deeper into its active repulsion capabilities.

-

Testing conducted using charged highland simulant produced the best active repulsion results, which is especially useful for Artemis missions.

Path to Flight

For TEST-RAD to reach the lunar surface by the year 2026, a series of testing milestones and design changes would need to occur. The path to flight would involve the following development stages:

-

An initial two-year implementation phase focused on testing and continued research in various relevant environments.

-

Next, there will be a year-long integration and verification phase in which designs and systems are finalized, and testing of TEST-RAD fully integrated into its system would take place.

-

Lastly, a year-long recombination and flight preparation would occur in which the technology would be prepared for launch and use on the Moon. We would develop methodologies and procedures to be used on the Moon to ensure TEST-RAD’s safe and effective use and test the system for stresses faced during flight, transportation, and landing.